GRADE 8-EIM-QUARTER-3-LEARNING OUTCOME 1- Prepare Electrical Supplies, Materials, and Tools

LESSON 1

Prepare Electrical Supplies, Materials, and Tools

LEARNING OUTCOMES: At the end of this Lesson, you are expected to do the following:

- LO 1. identify electrical supplies, materials, and tools;

- LO 2. request appropriate supplies, materials, and tools for a specific job; and

- LO 3. receive and inspect electrical supplies, materials and tools.

DEFINITION OF TERMS

- Ampere - a unit of measure of electric

- current Circuit - the path of electric current from the source to the components and goes back to the source

- Kilowatt - a unit of power which is equivalent to 1000w

- Conductor - a wire or a cord which provides path for current flow

- Resistance - the quality of electric current measured in ohms that resist the flow of current Hot wire - a wire through which current flows

- Insulator – material used to cover electric wires which may be made from plastic, rubber, or asbestos. Tools - are implements used to modify raw materials for human use

- Corrugated plastic conduit (CPC) - commonly known as flexible non-metallic conduit or the “moldflex”

- Metallic Conduits- metal raceways that was classified into four; rigid steel conduit (RSC), intermediate metallic conduit or tubing (IMC or IMT), electrical metallic conduit or tubing (EMC or EMT) and the flexible metallic conduit (FMC)

- Non-metallic conduits- plastic conduits or raceways designed to be a channel of wire that are classified as; rigid non-metallic conduit or the PVC, the flexible nonmetallic or CPC, and the surface plastic molding

- Connectors and Adapters - accessories that are used to connect from boxes to conduits or raceways to the other boxes in the electrical system

LEARNING OUTCOME 1- Prepare electrical supplies, materials, and tools

PERFORMANCE STANDARD

- Tools and materials are identified as per job requirement.

- Tools are classified according to its function as per job requirement.

- Materials are classified according to its uses on a specific project.

- Tools and materials are selected.

Electrical Tools and Equipment

Electrical task can be accomplished systematically to save time, effort, and

resources. Most of the work cannot be done using bare hands. To do the task, electrical

tools or equipment are needed to perform the job. This lesson will discuss the function/use of

each tool or equipment used in electrical wiring installations.

The following are common electrical tools and equipment needed in the installation

of electrical wiring.

I. SCREW DRIVERS. These

tools are made of steel

hardened and tempered at the

tip used to loosen or tighten

screws with slotted heads.

They come in various sizes

and shapes.

A. Standard/Flat Screw Driver.

The blade tip is wedge-shaped

and resembles a negative (-)

sign. This is used to drive

screws with a single slot head.

B. Philips Screw Driver. This

has a cross tip resembling a

positive (+) sign. This is used

to drive screws with cross slot

heads.

C. Stubby Screw Driver. It

comes in either Standard or

Philips screw driver with short

shank or blade and a shorted

handle used to turn screws in

tight space where standard

screw driver cannot be used.

D. Allen Screw Driver/Wrench.

This could be in the shape of a

screw driver or a wrench. Its

function is to drive screw with

hexagonal slot head.

II. HAMMERS. These are tools

used in driving or pounding

and pulling out nails. They are

made of hard steel, wood,

plastic or rubber. The following

are types of hammer:

A. Claw hammer

B. Mallet(rubber head)

C. Ballpeen hammer

III. PLIERS. These made from

metal with insulators in the

handle and are used for

cutting, twisting, bending,

holding, and gripping wires and

cables.

A. Combination Pliers (Lineman’s

Pliers). This is used for

gripping, holding, and cutting

electrical wires and cables and

even small nails. They are

usually used by linemen in

doing heavy tasks.

B. Side Cutting Pliers. This type

of pliers is used for cutting fine,

medium and big wires and

cables.

C. Long Nose Pliers. This is used

for cutting and holding fine

wires. This can reach tight

space or small opening where

other pliers cannot reach and

also used in making terminal

loops of copper wires.

IV. Wire Stripper- A tool used for

removing insulation of medium

sized wires ranging from

gauge #10 to gauge #16.

V.

Electrician’s Knife. This is used

by linemen to remove

insulation of wire and cables in

low and high voltage

transmission lines.

VI. Portable Electric drill. A small

drilling machine with a chuck

capacity of ¼‖ to 3/8‖. It is

used in making holes on metal

sheets and concrete walls.

VII. Hacksaw. This tool is used to

cut metal conduit and armored

cable.

Electrical Supplies and Materials

Electrical materials are developed and constructed for a special purpose such as to:

1. control the flow of current in an electrical circuit;

2. carry electrical current from the source to the load or current consuming apparatus;

3. hold and secure wires to its fixtures inside and outside houses and buildings; and

4. protect the houses, buildings, appliances’ and instruments from any destruction and

damage.

The following are the most commonly used electrical materials

MATERIALS AND DISCRIPTION

1. Convenience outlet- a device that acts as

a convenient source of electrical energy for

current consuming appliances. It is where

the male plug of an appliance is inserted

and usually fastened on the wall or

connected in an extension cord. It maybe

single, duplex, triplex or multiplex and could

be surface type or flush type.

2. Male plug- a device inserted to a

convenience outlet to conduct electric

current. A flat cord is attached to it on one

end and the other end is connected to a

current consuming instrument or appliance

3. Lamp holders- devices that hold and

protect the lamp and are also called as

―Lamp Sockets/Receptacles‖. These come

in many designs and sizes. They are

classified as flush, hanging (weather

proof/chain) and surface types.

4. Switch - a device that connects and

disconnects the flow of electric current in a

circuit. There are many shapes, designs,

and types and they are classified as

hanging, flush, and surface types.

5. Fuse - a circuit protective device that

automatically blows and cut the current

when and over load or short circuit

happens.

6. Circuit Breaker - a protective device used

to automatically blows and cuts the current

when trouble in the circuit such as short

circuit or overload occurs.

7. Junction Box - an octagonal shaped

electrical material where the connections or

joints of wires are being done. It is also

where the flush type lamp holder is

attached. This could be made of metal or

plastic (PVC) Polyvinylchloride.

8. Utility Box - a rectangular shaped metallic

or plastic (PVC) material in which flush type

convenience outlet and switch are attached.

9. Flat Cord- Is a duplex stranded wire used

for temporary wiring installation and

commonly used in extension cord

assembly. It comes in a roll of 150 meters

and with sizes of gauge # 18 and gauge #

16 awg (American wire gauge).

10. Electrical Wire/Conductor- electrical

material that could be:

a. Stranded wire which is made of multiple

strands joined together to make a single

wire.

b. Solid wire is made of a single strand of

copper or aluminum wire.

These are used

in wiring installation inside and outside the

buildings.

11. Conduits/Pipes- electrical materials used

as the passage of wires for protection and

insulation. These could be rigid metallic,

flexible metallic conduit (FMC), rigid nonmetallic (PVC), and flexible non-metallic or

corrugated plastic conduit (CPC)

12. Clamps- electrical materials used to hold

and anchor electrical conduits in its proper

position

13, Connectors- used to attach metallic or

non-metallic conduit to the junction or utility

boxes

COMMON WIRE SPLICES AND JOINTS

Introduction: As a student in Electrical Installation and Maintenance you should acquire the

important knowledge and skills in wire splices and joints and should be familiar with the

actual application of every splice and joint. This will serve as your tool in performing actual

wiring installation. Of course, another factor is the knowledge in interpreting and analyzing

the wiring diagram especially if the circuit is complicated.

The following are the Common Electrical Wire Splices and Joints.

Rat Tail or Pig Tail. This kind of joint is

commonly used to join two or more

conductors inside the junction box. It is

suitable for service where there is no

mechanical stress when wires are to be

connected in an outlet box, switch, or

conduit fitting.

Y-splice. This method of wrapping is

generally used on small cables because

the strands are flexible and all can be

wrapped in one operation.

Knotted tap. This is used where the tap

wire is under heavy tensile stress.

Plain tap joint. This is used where the

tap wire is under considerable tensile

stress circuit.

Aerial tap. This is used as a temporary tap usually done in constructions sites. The

easy twist will facilitate tap wire movement

Duplex cross joint. This is a two-tap

wire turned simultaneously and is used where the two tap wire is under heavy

tensile stress.

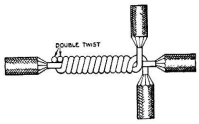

Western Union Long Tie. This is used

extensively for outside wiring to extend

the length of wire from one end to

another.

Cross joint. The same application is done

as in plain tap and the only difference is

that this tap is a combination of two plain

taps place side by side with each other.

Wrapped Tap or Tee Joint. This is

used on large solid conductors where it

is difficult to wrap the heavy tap wire

around the main wire.

EXTENSION CORD

An extension cord is a span of flexible electrical power cable with a plug on one end

and multiple sockets on the other end. It comes in several varieties to suit the needs of the

user. One of the most important considerations is the power handling capacity to make it

safe and functional.

Electrical gadgets are product of modern technology to make our life better. The

number of electrical gadgets available at home and in offices may exceed the existing

convenience outlet installed in every room. The best remedy to address the insufficiency of

available outlet is to use an extension cord especially if the electrical gadgets need to

operate at the same time.

QUIZ # 1- Direction. Identify each of the following tools/materials

PERFORMANCE TASK # 1- SKINNING OF WIRE USING DIFFERENT TOOLS AND EQUIPMENT

DIRECTION. Given are sets of tasks and their corresponding pictures, practice those using appropriate tools and materials. Your performance will be judged using the following criteria:

PERFORMANCE RUBRICS:

- Accuracy- the ability to follow the procedures/directions with precision.

- Workmanship- the art, skill and finality of work.

- Proper handling of tools- the ability to apply proper handling of tools for a given task.

- Speed- efficiency of work.

TOOLS:

1. Combination Plier

2. Side cutting plier

3. Long nose plier

4. Wire stripper

5. Electrician’s knife

PERFORMANCE TASK #2 - A CONNECTING SKINNED WIRES TO WIRING MATERIALS

OBJECTIVE: To be able to properly connect skinned wires to bulb receptacles, convenience outlets, switches, or any other wiring materials.

TOOLS

1. Combination pliers

2. Side cutting pliers

3. Long nose pliers

4. Wire stripper

5. Electrician’s knife

6. Phillips screw drivers

7. Flat screw drivers

MATERIALS:

Electrical wires used in Activity 1.1

PROCEDURE:

Follow procedure on the table below

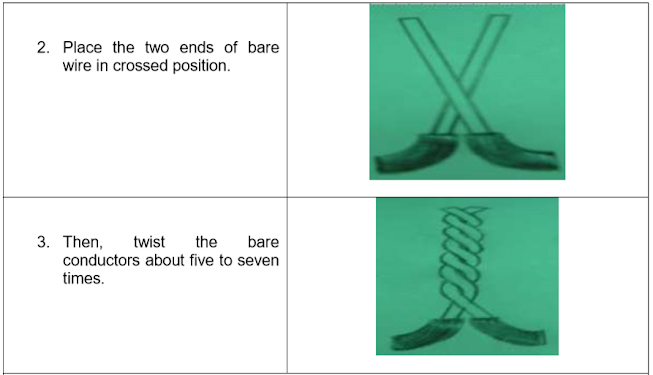

PERFORMANCE TASK #3- SPLICING OF WIRES

DIRECTIONS: Below are pictures of common wire splices and joints used in electrical wiring installations. Practice doing the task by following the steps given.

Your performance will be judged using the rubric:

ACTIVITY 1.

A. Direction: Inside each piece of puzzle are jumbled letters. Arrange these letters to form the correct word on types of joints and splices/wire connections.

1.__________________________________

2.__________________________________

3.__________________________________

4.__________________________________

INTRODUCTION

Underwriter’s knot is one of the skills needed in making an extension cord. It is neither a joint nor a splice but a knot that is made in an extension cord. Its purpose is to relieve the strain on small wires of the cord and binding screws of convenience outlets and male plug.

PERFORMANCE TASK #4- For you to make a quality and safe output you have to strictly follow the given procedure in making an underwriter’s knot. Below is the procedure.

You will be rated by the use of this performance rubics.

PERFORMANCE RUBRICS:

Materials:

Flat cord no.18 AWG Tools:

Side cutting

long nose

combination pliers

Wire stripper/electrician’s knife

PROJECT PLAN IN MAKING AN EXTENSION CORD

INTRODUCTION

You might be wondering why there are several projects which are not completely done. Well, there are several reasons why this happens. It might be out of budget or not properly planned. So, this Lesson will help you achieve the desired quality project.

A project plan is necessary before undertaking any project because it serves as your guide in accomplishing an activity. It will give you an idea what needs to be done, how much to spend and what procedures to undertake.

A well prepared project plan saves time and cost of materials. Below is a sample project plan of an extension cord. This format can also be used in preparing a plan for other projects in the future.

PERFORMANCE TASK #6- Project Plan - (Making an extension cord)

Name of Student:_________________________

Year & Section:__________________

I. Name of Project: Extension Cord Assembly

Date Started: ___________________ Date Finished: __________________

II. Objective:

a. Demonstrate how to make an extension cord. b. Observe safety measures while doing the project.

III. Sketch/Drawing:

IV. Materials Needed:

V. Tools and Equipment Needed:

- 1. Standard/Flat Screw Driver

- 2. Philips Screw Driver

- 3. Long Nose Pliers

- 4. Side Cutting Pliers

- 5. Electrician’s knife/ Pocket knife

- 6. Continuity Tester or Multi-tester

VI. Procedure:

- 1. Prepare the plan.

- 2. Gather all necessary materials, tools and equipment needed.

- 3. Insert cord into the male plug, split the cord wires about 8 centimeters long.

- 4. Remove insulation of both wires 1 centimeter long with a pocket knife as if sharpening a pencil. Be careful not to cut any strand.

- 5. Scrape bare wire with the back of the knife until shiny. Twist the wire stands.

- 6. Tie the underwriter’s knot.

- 7. Make a loop on terminal wires and connect the wires to the screw of the male plug. The loop should go with the thread clockwise direction.

- 8. Split the cord wires at the other end about 4 centimeters long, then follow procedure no. 4.

- 9. Connect the wires to the connectors.

- 10. Open the convenience outlet then remove the screw.

- 11. Insert the wire connectors to the screws, tighten it and return the cover.

- 12. Check the continuity and test the extension cord.

- Accuracy- the ability to follow the procedures/directions with precision.

- Workmanship- the art, skill and finality of work.

- Proper handling of tools- the ability to apply proper handling of tools for a given task.

- Speed- efficiency of work.

Mga Komento

Mag-post ng isang Komento